The Sustainable Manufacturing Revolution: Transforming Industry for a Greener Future

Discover how innovative technologies and practices are revolutionizing manufacturing to create a more sustainable and environmentally responsible industry.

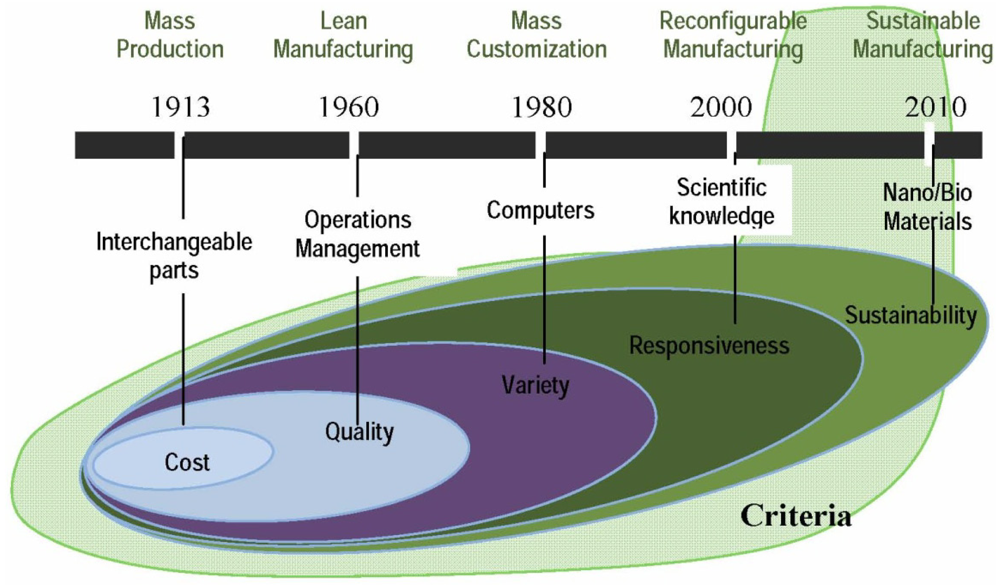

The manufacturing sector is undergoing a profound transformation as companies worldwide recognize the urgent need to reduce environmental impact while maintaining productivity and profitability. This sustainable manufacturing revolution is driven by innovative technologies, changing consumer demands, and the growing imperative to address climate change and resource depletion.

The Driving Forces Behind Sustainable Manufacturing

Several key factors are accelerating the adoption of sustainable manufacturing practices across industries:

Environmental Regulations and Standards

Governments worldwide are implementing stricter environmental regulations, requiring manufacturers to reduce emissions, minimize waste, and adopt cleaner production methods. These regulations are creating both challenges and opportunities for innovation.

Consumer Demand for Sustainable Products

Today's consumers are increasingly conscious of the environmental impact of their purchases. They're demanding products that are made sustainably, with transparent supply chains and minimal environmental footprint.

Economic Benefits of Sustainability

Sustainable manufacturing practices often lead to cost savings through reduced energy consumption, waste minimization, and improved resource efficiency. Companies are discovering that going green can also mean better financial performance.

Key Technologies Transforming Manufacturing

Additive Manufacturing (3D Printing)

3D printing is revolutionizing manufacturing by enabling on-demand production, reducing material waste, and allowing for complex designs that were previously impossible. This technology significantly reduces the carbon footprint of production processes.

Internet of Things (IoT) and Smart Manufacturing

IoT sensors and connected systems enable real-time monitoring of energy consumption, production efficiency, and environmental impact. This data-driven approach allows manufacturers to optimize processes and reduce waste.

Renewable Energy Integration

Manufacturers are increasingly turning to solar, wind, and other renewable energy sources to power their operations. This shift not only reduces carbon emissions but also provides long-term cost stability.

Best Practices in Sustainable Manufacturing

Leading manufacturers are implementing comprehensive sustainability strategies that include:

- Energy efficiency optimization and renewable energy adoption

- Waste reduction and circular economy principles

- Sustainable materials sourcing and green chemistry

- Water conservation and treatment systems

- Employee training and engagement in sustainability

- Lifecycle assessment and environmental impact measurement

The Future of Sustainable Manufacturing

As we look toward the future, sustainable manufacturing will become the standard rather than the exception. Companies that embrace these changes now will be better positioned to compete in an increasingly environmentally conscious marketplace.

Ready to Transform Your Manufacturing?

Learn how GLO Standards can help your organization implement sustainable manufacturing practices and measure your environmental impact.

Contact Us Today